Improving communication & decision-making with technology in oil & gas

New digital platforms are transforming how oil and gas companies connect teams, share data, and optimize complex operations.

The oil & gas industry is by far one of the most complex industries in the world.

In this sector, operations are usually spread across various countries and regions, often in remote locations.

The industry struggles with challenges related to communication, decision-making, and data silos, which can lead to significant inefficiencies and risks.

However, these challenges can be addressed with the right approach to digitization and digital technologies.

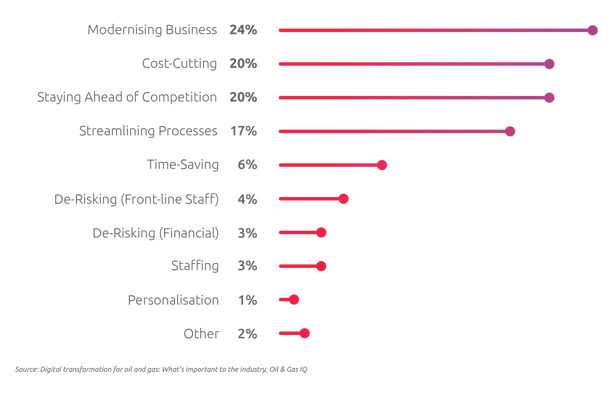

Some time ago, Oil & Gas IQ published a report showing key drivers for companies operating in this industry. Here are the answers:

The biggest driver (almost a quarter of the respondents said so) behind digital transformation projects in oil and gas is modernization of the business.

So, why is it so vital to modernize oil and gas companies and their operations?

The short answer is that modernization in most cases leads to enhanced data capture and sharing capabilities, which in turn leads to efficiency and profitability.

For a more detailed response, read on.

The importance of modernizing a business

In order to operate effectively, oil and gas companies require access to real-time information and data to make informed decisions. The lack of effective communication and operations can result in the following problems:

- Delays

- Lost production

- Increased costs

Thankfully, modern digital technologies have come to the rescue. We want to tackle several essential areas that can be modernized with advanced tech.

Predictive analytics improve decision-making

With advanced data analytics solutions in place, oil & gas companies can gather, clean, process, and evaluate seismic data, as well as combine it with other datasets, to identify optimal drilling locations. Data analytics is also used to optimize drilling operations by identifying non-production time using real-time logging information and then enhancing the drilling process.

All these applications are currently backed by modern AI and machine learning technologies that are capable of analyzing large datasets and providing users with actionable insights that can be used to improve daily operations.

With AI, oil and gas companies can:

- Pinpoint optimal areas for drilling (production optimization)

- Analyze the economic viability of a specific drilling project (production cost optimization)

- Benefit from predictive asset maintenance (including preventing accidents and glitches)

- Optimize inventory management, scheduling, and procurement

Breaking down data silos streamlines communication

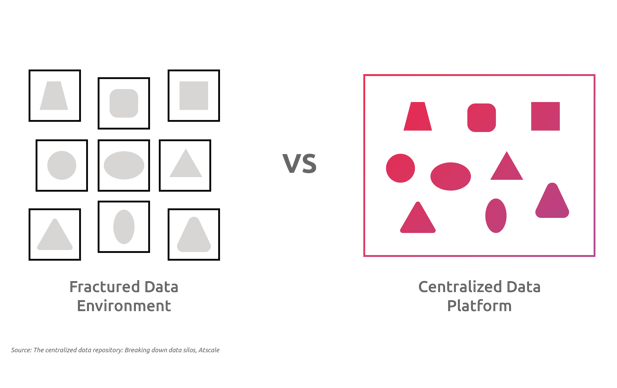

Another critical aspect of digital technology is the ability to break down data silos. In the past, data was often isolated in various departments and systems, making it difficult for companies in this sector to access all the information they needed.

This problem is still common in the oil and gas sector, especially given these companies operate in many different locations.

However, with the advent of digital platforms and tools, data can now be centralized and made accessible to all users and stakeholders.

Here, the cloud plays a crucial role. Cloud-based data integration tools can be used to integrate all the relevant data sources in your business and create one centralized data repository for all the data your company needs.

As a result, different teams, employees, and departments can communicate with each other more effectively, and all interested parties have access to the same updated information. This makes work far more effective and less time-consuming.

Data sharing streamlines exploration, development, and management

Real-time data sharing is the lifeblood of the oil and gas industry. Shared data resources identify individual resources and activities within the enterprise, thus serving as a vital carrier of all information pertaining to the exploration, production, operations, and management activities. Without real-time data-sharing capabilities, the industry would struggle with digital transformation, which is a crucial factor in modern business.

In a nutshell, data sharing in the oil and gas industry can offer these values:

- Firstly, it actively contributes to exploration and development by enabling industry players to realize the most efficient, scientific-based methods for streamlining operations.

- Secondly, data sharing enables companies in the oil and gas industry to analyze trends and determine the demand for oil resources among consumers. This enables companies to innovate accordingly and steadily develop potential markets in a way that matches demand without over-exerting the company's pipeline and other distribution mechanisms.

- Thirdly, data sharing could also help oil and gas companies attain greater profits by preventing losses due to spills. By incorporating detection systems throughout the pipeline and centralizing their information-gathering systems, oil and gas companies can promptly detect and act upon spillage and fire hazard issues, thus mitigating their losses.

IoT integration with remote collaboration tools can transform the industry altogether

Data in the oil and gas industry is a precious commodity.

That's why modern companies protect their trade secrets and proprietary technology.

However, this wasn't always the case. During the industry's inception, data was shared openly, leading to rapid, monumental growth across the sector.

This rapid growth has, however, slowed down over the past few decades due to the industry players' reluctance to share data.

The energy sector is replete with numerous complex procedures, distributed systems, and significant hazards, which, if not managed correctly, could impact the company's operations on-site and at its distribution centers.

Drilling

By leveraging IoT integration throughout their operations, companies could potentially mitigate problems before they become a major cause for concern.

Take drilling, for instance.

IoT devices give companies remote monitoring capabilities that enable them to detect issues like pressure changes and other signals that indicate potential issues with the process.

Similarly, integrating IoT systems throughout the pipeline can help mitigate environmental catastrophes like leaks, which threaten the companies' livelihood and reputations.

With remote collaboration tools like IoT sensors and geotagging data, companies can get ahead of the problem faster since they have the exact location of the damage and information about its severity.

Take a look at one such system:

Transportation

IoT could also streamline transportation. Despite the collaboration among field and office managers, fleet managers are somehow left out of the loop. This leaves them with no choice but to rely on satellite data, which is quite restrictive, especially when determining the status of their ship and cargo.

However, by aggregating data from satellites linked with data from other sources, fleet managers can detect issues like fires and leaks on the ship and mitigate them promptly. Having a clear communication channel with their counterparts on land can also help fleet managers avoid dangerous situations on the sea, like geopolitical conflicts, which spring up at a moment's notice and risk cargo ships in the area.

Wrapping up

In conclusion, the oil and gas industry faces significant challenges in communication and decision-making due to its geographically dispersed operations and data silos. However, with the proper use of digital technologies, these challenges can be addressed, leading to significant improvements in communication and decision-making. It is important to stay up-to-date with the latest digital technologies and their application in the industry to help stakeholders optimize operations and improve outcomes.

Share this

You May Also Like

These Related Stories

Building a future-ready enterprise: The journey to digital transformation

Bridging the gap between legacy systems and digital innovation